A reproduction of a Churburg arm harness. Helped along by the friendly armouring groups on facebook.

An enclosed helmet is the predecessor to the well known great helm that was used in the late 12th and early 13th century, which has a flat top, complete coverage at the front with a face plate and partial coverage around the sides and back. There are relatively few artifacts or depictions showing this form of helmet (at least freely available on the internet, that is) so there was a fair bit of interpretation as to the exact form and construction on my part for this. This was informed from some of the depictions in illuminations and also from other modern reproductions.

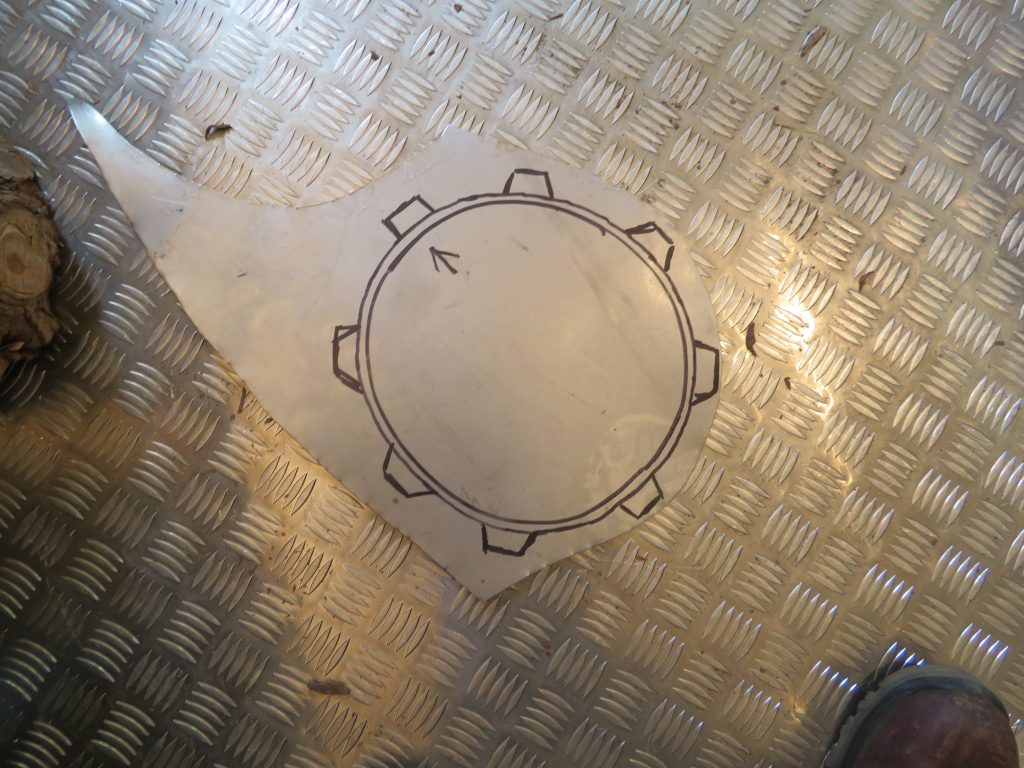

I began by sketching A plan for how I wanted the helmet to look and fit on a head. I planned a construction from four pieces: A face plate; a smaller back-of-head-plate; A long plate around the top of the head; and a circular top plate.

I then planned out the pattern for each piece. I started by taking measurements from my head with a fabric measuring tape. I made each piece over sized as it is very easy to cut them down later, but much harder to make them bigger.

I worked out the pattern for the upper plate using an online calculator for the net of a conic frustum, which gives it the larger diameter at the top than the bottom. I made a few versions of this pattern with different parameters and tried them on to determine the right proportions. I largely eye-balled the shape for the front and back plates patterns based on the upper plate pattern I selected and a few key measurements from my head. I didn’t make a pattern for the top plate as I would need to make that to fit one I had already shaped the rest of the helmet.

I marked up the parts onto steel sheet from the pattern and cut them out using hand shears. These can be somewhat tricky to use, mine definitely have a bit of a knack to them and I remember I used to struggle with cutting larger pieces out. I have found that it it much easier to cut out the pieces with lots to spare around the edges initially and then go back and cut closer to the line on a second pass. This means you aren’t trying to make accurate cuts and sharp turns while there is a large amount of material, which is harder as the shears work by bending the off cut away, which is harder when there is more material to bend.

I then de-burred the edges and cleaned off the surface rust with 60 and 80 grit flap disks on the angle grinder (I wouldn’t recommend flap disks for this as I have found they seem to leave a surface finish that makes things more difficult when it comes to polishing). Finally I remarked the areas where plates were going to overlap.

The upper plane was simple to shape as it only curves in one plane. I bent it by hand over a ring mandrel held in a vice, which was standing in for the horn of an anvil. I continually moved it and put small amounts of bend in at each point to give a smooth curve. At each end it becomes difficult to bend by hand as the leverage gets smaller and I needed to use a leather mallet. This is where I really missed having an anvil as the long lever action of the ring mandrel in the vice meant I could only get a few hammer blows in before I had displaced the mandrel and had to reset it in the vice. Once the part was shaped I punched 3 holes on the overlaps and temporarily secured them with bolts.

I shaped the front plate with a combination of dishing into a stump and raising over a mushroom stake to make the curvature for the fave plate. I then added a crease towards the top over a blunted chisel. Finally, I plannished the surface to remove the hammer marks.

I then married up the face plate and the upper plate to work out where they should overlap and marked up where the eye holes should go. In marking up the eye holes I had to account for the fact that I would roll over the bottom of each, which would make the holes larger. I cut out the eye holes using a combination of hand shears, a slitting disk on a dremel, and hand files.

Shaping the back plate was somewhat more difficult that the first two as I wanted it to flare out meaning it was curving in opposing directions on each axis, which is going against how the metal wants to move.

Once these plates were shaped I punched holes around the overlaps and temporarily secured them with bolts.

By far the most challenging part of this was shaping the top, which took me three attempts. The difficulty is that to join the top to the upper plate there needs to be a bend of more than 90 degrees all the way around the rim, which is creates a lot of excess material. Due to general frustration throughout this process I forgot to take many pictures.

In my first attempt I started by using the shape from the already assembled parts to mark out the top plate. I thought that adding some curvature to the top would make adding the bend around the edge easier as it would no longer be need to be such a large angle. This was not the case as it meant the whole piece started to warp making lining it up with the upper plate more difficult. I had initially hoped to have a solid rim all the way around but this was quickly proved not to be feasible so I cut four slits around the rim to remove some of the bulk and make bending it easier.

After a while working on this I decided I wasn’t going to be able to make it fit and to start with a fresh piece.

My plan for the second attempt was for the top to fit inside the upper, rather than outside, which was the plan for the last version, and to leave the top flat while I made the bend around the edge, which was only going to be a small amount of material with tabs around the circumference.

The main flaw in this attempt was the idea for the top to fit inside the upper plate as it quickly became obvious that this was going to leave a significant air gap.

In the third attempt I decided to return to having the top fit on the outside and to have tabs all the way around. This proved to be much more successful and, once I had bent all the tabs mostly over I added a slight curvature to to top.

I then polished up each plate going through a successively finer grits of sandpaper followed by polishing compound on polishing wheel. To protect the inside from rusting I painted the inside of each plate with black paint.

Finally I riveted all the plates together. The rivets around the brow band also held the suspension system in, which I made simply from triangles of leather each with an edge riveted to the helmet and then the remaining corners of each all loosely tied together. This system means that the metal of the helmet is not resting on your head, which would mean any impact would just be directly transferred, very similar to the suspension you find in modern hard hats. I am not sure this system of leather riveted directly to the helmet is particularly historical, from what I have seen helmet liners would more usually be textile and would be sewn to the helmet or to a second strip of leather that is itself riveted to the helmet. These systems allow the liner to be more easily replaced without having to grind out and replace a lot of rivets. Knyght Errant has a good video on the helmet suspension systems for those who are interested.

A buckler is a small shield held in the hand (rather than strapped to the arm). This was largely a project for practicing dishing and trying to get greater depth and cleaner edges than I had managed previously. Later ( after I got bored with polishing) it also became an experiment in oil-blackening. This isn’t really based on any particular example and as such makes no particular claims of historical accuracy.

The start of this project was to carve out a dishing stump. I cleared out the bulk of the material with a handaxe ( Those wild cuts are from when the stump was previously used for chopping wood, i’m not THAT inaccurate) and then smoothed it out using a flap disk on an angle grinder.

I cut a circle out of sheet mild steel with hand shears, taking a rough guess at the size I wanted and adding extra diameter to account for reduction during the dishing. I overestimated how much reduction there would be so it ended up being larger than I intended. This was due to the fact that I was only dishing a section in the middle and leaving a wide rim around the edge, which would not get pulled in, meaning basically all the movement was from stretching and thinning the material rather than pulling it through.

I then marked out a circle for the size of the boss (bump in the middle) that I wanted and began a series of passes of dishing. This simply involves beating the metal down into the depression of the dishing stump, which I did using a 2 pound ball peen hammer. This was a newly purchased hammer, which I intended to add something with a bit more heft to my collection of hammers (most of the rest are really silversmithing hammers which aren’t big enough for larger jobs in steel) but after a long time away from bashing things with hammers this was initially rather heavy for me. A summer making armour does wonders for your right arm strength though.

As you can see in the pictures the dishing introduced some warping in the rim, which I had to work out. Once I had got the depth I wanted I planished it and went around the edge hitting it from the inside against the curved edge of my psudo-anvil (lump of iron I have gone at with an angle grinder to make different shapes) to make a clean edge to the boss.

I then rolled over the edge. I started by cleaning the surface o f the part that was going to be folded over to prevent rust being trapped in side. I then marked out about a centimeter in around the outer edge. I rolled the edge on this mark by beating it over a steak. I then made the base for the grip by bending a strip of steel. I cleaned the whole surface of both parts with successive grits of flap disks on the angle grinder and some hand sanding, which was a very non ideal process that lead me to get bored and decide to try oil blackening it instead.

I had done a tiny bit of oil blacking in engineering ( read: metalwork) GCSE a long time ago and some cheats blackening with stove black on the armouring course I went on but I needed to do a did a bit of research to work out what the proper process would be. This yielded two main facts: that you could really use any kind of oil; and that there were broadly 2 possible methods. You could either heat up the whole piece and then quench it in the oil or heat the piece and then wipe on the oil a section at a time. I would have to go for the second option as I had neither a method for heating the whole piece or enough oil to hand to fill a vat of sufficient size to dunk the whole shield in it. As to the choice of oil, I selected olive oil purely for its virtue of being quickly acquirable through a raid on the kitchen. To heat the buckler I used a propane torch.

After heating up the whole buckler and surrounding area I worked on a process of heating an area of the shield, applying the oil with a spray bottle and a rag, and then heating that area from the opposite side to bake on the oil until it reached the desired colour. The problem I encountered was that in some cases the oil would some how ‘burn off’ and patches would return to the silver colour of the metal. This seemed to be related to areas getting too hot as once this happened this area would remain stubbornly un-oiled no matter how much oil an heat was applied until the whole thing was allowed to cool completely and the process started again. Over three attempts the buckler moved through a yellow colour, to brown, and finally had an even shiny black finish.

I then fitted wood on either side of the metal for the handle, securing them with large rivets sold for attaching spade heads with. I painted the backside of the buckler with black paint. Once the paint was dry I drilled two holes on opposite sides of the rim and riveted the handle on to the buckler.

(Shout-out to my father’s hand for being in this picture)

Overall this was a relatively simple piece of metal work that served as a good project to get back into the swing (pun very much intended) of hitting things with hammers. Learning oil blacking is also pretty valuable as it was a commonly used finishing technique for armour historically and, crucially, is much less tiresome that polishing things.

Last year I went on a short course in armouring at west dean college. This was enormously enjoyable and also gave me a better grounding in the techniques to be able to take on some more challenging pieces of armouring over this past summer (some of which will have already been posted when this article is released).

Obviously as this was from a paid course I won’t provide any instruction but here are the progress pictures I took at the end of each day.

This is the first of a series of backlog posts covering things i have been doing but never got around to writing about. Last December I did a silversmithing course to learn how to use the tools I inherited, as my previous attempts had been broadly unsuccessful, particularly in the realm of soldering. On this course I learnt a number of techniques including sawing (after breaking a great many blades), soldering, granulation and stone setting. After practicing on a number of pieces in copper I made two pieces in silver: A ring and a necklace.

The necklace was based on an amber doughnut I had that was previously hung on some leather lace. The challenge for this was to make a setting that would allow the amber to spin freely. The solution is shown bellow in cross section. The key is in the granulation (silver melted into a ball) in the hole of the stone, which prevents it from falling out.

The ring is fairly plain with a black opal in a Cabochon setting with granulations on each side. The tricky part of this was soldering all the parts on without melting the previous solder off, since the balls on each side had to be done separately ( The ring had to be on its side so they didn’t slide off) and hard and medium solder (which melt at a higher temperature) had already been used to solder the ring shank and stone setting.

I made a Gothic gauntlet following a tutorial series on youtube by Greenleaf workshop (

https://www.youtube.com/playlist?list=PL_DVxRBaoNVUvXE1kywNLrH6edNVmUz25 ). Here is the process presented in video format.

A while ago I got a large amount of my grandfathers old silversmithing tools that had been sitting in storage for ages. With the tools was a reasonable amount of silver as well so I figured I would try my hand at making some jewelry. That never really worked because I couldn’t get the soldering to work properly so instead I decided to basically reuse skills I already had and do a bit more dishing (see article on making a helmet) and the best way I could think to do that was to make a uselessly small bowl. making the bowl, doesn’t actually only require dishing, I also used raising, which involves increasing the curvature by hammering the piece over a ball stake (raising doesn’t always have to be on a ball stake, it can be on many different shapes but in this case it was a ball). I have to admit that my memory is not very good for this project so I do not know how I did specific bits such as small convex curve at the bottom or the rim.

For the dishing I used A tool called a doming block and a small ball peen hammer. This was simply hammering into the appropriately sized form until roughly the right depth was achieved. At that point I moved onto raising. The advantage of raising over dishing is that it can be used to give more varied curvature than dishing, as you can hopefully see the in the edge of the bowl. The process for raising is fairly like dishing but in reverse. The piece is placed on the stake with the convex side facing up and then, using a flat narrow headed hammer, you strike slightly away from the point of contact between the piece and the stake, which move that bit of the metal down into the space. Then move the piece round and repeat around the surface until the desired shape is reached.

The rim is flared out and also curved under itself to give a clean rounded edge. I am now not sure in which order I did these operations. I am thinking that it is more likely that I flared out a double width rim and then folded half of it back under. To do this I would have to hammered it around a sharp edge of some sort but I do not remember exactly what I used. Once it was done I hammered around the rim with the edge of a square hammer against a flat surface to put in the decorative lines.

For the dent in the bottom I think the most likely way I did it is, once the rest was finished, I placed it upside down and then just hit the bottom with a ball peen hammer.

Then to finish it up I polished it up with some emery polishing paper and then a small polishing wheel on a Dremel.

That concludes the making of a tiny and useless bowl. It is mainly good as an exercise for practicing techniques on a smaller scale.

Armour is probably one of my favourite things and what really got me into making things. I had always liked craft but digging into information about making armour on the internet (large amounts of it wildly inaccurate) was what got me properly interested in taking on some more substantial projects, the first of which was this helmet which I made ~5 years ago. The helmet in question is a type of nasal helmet (referring to the bar sticking down covering the nose) called a spangenhelm, which is a word of German origin referring to the strips that form the frame of the dome of the helmet. Its is a design from the early middle ages which is fairly straightforward to construct and was later superseded by helmets of the same basic shape but with the skull constructed from a single piece of metal which, while being sturdier are a reasonable amount more tricky to make. The main difference as far as I am concerned being that heat would be required whereas with the spangenhelm, while it would be easier with heat, it is possible to make do without (this is only the case for modern people with access to pre-rolled sheet steel, historical smiths would not have this this luxury).

As this project is so old I will not be able to do a complete tutorial and some of the steps may be slightly vague. If you want to make a similar project then I would suggest doing a bit further research.

My helmet has a number of issues, the foremost being that is doesn’t really fit me. This is partly due to it being completely circular around the brow, rather than something a bit closer to the actual shape of a head. It is also partly just down to being a bit too small, which is most noticeable when you are trying to put it on as the cheek plates will have a bit of a fight with your face as you try to do so. There are also a few issues with the shape relative to historical examples. Typically nasal helmets seem to be fairly conical in shape rather than the more spherical dome I ended up with. Thinking about this now I would say that this is because the shape I used actually presents a relatively flat surface on the top, meaning any blows from above (which is really where a large number of blows would come from) would not glance and would transfer most of their energy through to the wearers head. On the other hand a conical design would provide a better glancing surface and thus better protection.

The other thing that I notice looking at more examples is that the nasal is usually flat and even when it does have an angle put into it it is much less pronounced than the one I put on mine. This is a bit harder for my to work out as it seems like my design would be stronger and less likely to give way if it were struck. My guess is that the angles on my design may run the risk of redirecting thrusts into the wearers eyes, though I think that in any situation where this were to happen the result would be pretty similar if the the nasal were flat.

One important element that is missing entirely is the leather suspension that would run around the inside of the helmet and cause it to float above the wearers head rather than the steel sitting directly on top of your head (equivalent to what you would see on the inside of a builders hard hat) . Without this the helmets effectiveness is greatly reduced as, even with padding, and impacts are largely transferred directly though the helmet into the wearer’s head.

The final issues with the helmet are simply issues of execution: It is overall slightly lopsided and the overall finish is not as good as I would like it to be if I were to remake this project now.

The main process used for making the helm is ‘dishing’, which is in principle fairly straightforward. Dishing involves hammering a piece of sheet metal into a concave recess in order to curve the metal in multiple directions. It requires two tools: a dishing stump and a hammer.

A dishing stump is most commonly made from a fairly large tree stump (hence the name) but really any bit of wood will do. Ideally it should be reasonably substantial so as to have enough mass as to not bounce around every time you hit into it. What I ended up using was a rather lightweight tall thin-ish bit of wood that was left over from some building work that had been done on our house (looking back at the picture of the helmet you might notice that its sitting on a stump that looks pretty much like what I initially described and wondering why I didn’t use that and to be honest so am I). Once I had selected my stump I then cut a concave bowl shape out of it with a chisel and hammered inside it to compact the wood and harden the surface. The exact shape is not hugely important as you are not hitting the metal into the inside surface of the form, just in to the space. All the form needs to have is an rim that will support the piece and a void into which you can push the metal. As for the hammer you need something with a reasonable amount of weight to it and a fairly rounded surface without any sharp edges. The hammer also needs to be of an appropriate size to fit your dishing form.

The first thing to do before starting hammering away at metal is to work out the pattern. This is a stage that I didn’t execute particularly well, which Is why my helmet didn’t really fit properly. To work out the pattern start with a measurement around the circumference of your head and then add on a fair amount to allow for padding. Use this measurement to make a long thin rectangle (out of card at first), which will be the brow band running around your head. Then you need to measure over the top of your head front to back and left to right (again adding on some extra for padding) and make two more long thin rectangle to these measurements to from the bands that go over the top of your head. now put these pieces together and try out the card version of your helmet and see if it works. If it doesn’t go back and adjust your pattern. Once you are happy with the pattern you can then cut these pieces out of some sheet metal using shears. Then take a file to the edges of the pieces to clean them up and remove any sharp bit left from the cutting.

Now to curve the these pieces. This can be done using the dishing stump or, as they only need to be curved in one direction, just by hand. It is important to not give them perfectly circular curves and instead ones that are closer to the shape of your head. Once this is done the strips need to be attached together, which will be done by riveting. First holes need to be put in, this can be done with either a punch or a drill. Using a punch is easier when holes are near the edge but for some holes later in the build using a punch will not be possible so a drill will be necessary anyway. To rivet the pieces together I used nails. Placing them through the holes with the head on the inside then cutting them down leaving a small amount protruding and peening that down with a hammer against a hard surface.

Once the frame is together I then used that to create the pattern for the plates that fill the gaps. To do that I the rolled the frame on a piece of card, tracing the line given by the inside of one of the gaps. Then I expanded that shape by ~2 cm in each direction to give the overlap that is needed to rivet the pieces together. I did this for each of the spaces to produce a specific pattern to fit each part of the frame.

At this point is where we finally get to use the dishing form we made earlier. Once I cut out and prepared each part as I detailed previously I then started dishing each one. Dishing is a fairly slow process (especially if you are doing it without heat), requiring many passes to create a significant amount of depth. It is done by starting in the middle of the piece and working out to the edges in circles. I found it best to be striking with the hammer in the same place towards the edge of the form nearest to me and turning the piece around to move where I was hitting. Each hammer blow doesn’t need to be particularly hard, just slowly work around the piece and then start another pass. As metal is worked it becomes ‘work hardened’. The stress you are applying to it causes its internal structure to change and make it harder which means it will be more difficult to work with. If you are able to then it is best to anneal the piece when it starts to go too hard, which involves heating it up and then letting it cool to return it to its original hardness. I managed to get away without annealing anything so this should be achievable without but it would be easier if you are able to do so. Once the piece is starting to get close to the final shape try and fit it into place between passes to see what bits need more work to get it to the correct shape.

Once I had made all the plates it was time to rivet them into place, which I did by the same method described earlier. For the first plate all the holes can all be made through both the frame and the plate simultaneously using a punch. For some of the later plates it isn’t possible to reach with the punch so A drill has to be used instead. I found it was easier to punch the holes into the frame first before putting in the plate and then, once the plate has been fixed in place along the bottom, to drill through using the holes in the frame as a guide.

For the final parts (the nose and cheek guards) much the same process is followed. The pattern can mostly just be designed arbitrarily as it isn’t particularly important how these parts fit together. The only real difference is for the nasal. If you wan’t to put a crease down the middle then use something like a blunted chisel or an old axe head and hammer the piece over that then use something hard with a a sharp right angled edge to increase the angle if you wish.

The final stage is to give it a surface finish. I would recommend painting the inside as it will provide good long term rust protection. For the outside you could polish it, oil black it or paint, which was done historically more than we think partly due to over zealous 19th century museum curators polishing away historical paintwork.

That concludes the building of the helmet. If you make one be sure to clean it regularly so as to prevent it from rusting, which is what I didn’t do with mine and it is currently is quite bad condition. Armour is definitely something I would like to come back to and I am working on some ideas for a second helmet, though that isn’t likely to see any work until next summer unfortunately.

Who doesn’t love swords? well I don’t like them quite as much as I did after the hours I have put in making this one, messing it up and having to try and rectify my mistakes and generally making a bit of a meal of it. I started this project almost 2 years ago, largely interrupted by the small inconvenience of going to university but even with that it still ended up being quite a lot more work than I had originally anticipated. With that in mind, if you are here looking for a tutorial on how to make a sword you are in the wrong place. My main advice to anyone considering trying to make a sword would be ‘don’t’ at least not until you have honed your skills on smaller things, I think a knife would be a much better place to start rather than diving in at the deep end like I did. My second piece of advice would be to avoid doing a fuller (the groove running down the middle of the blade commonly, and incorrectly, called a blood groove) as without more advanced tools getting a good fuller is pretty difficult, time consuming (you will notice mine only goes half way up the blade) and you run the risk of, as I did, putting a hole in your sword. For those of you who are not deterred by this (or are just interested) I will give an overview of what I ended up with and the process by which I made it.

What I Made

Despite what this article is named I didn’t make a sword, not really anyway. If you were to use this in battle you would be in a bit of trouble, for one thing it is about as sharp as a butter knife with the only vaguely offensive part being the point, it is also only made of mild steel which makes it rather soft and, at the thickness it needed to be to have a balance similar to a functional sword, very floppy. So in reality what I made is something that looks like a sword and feels a bit more like a sword than a stick but is pretty much just a decorative item.

How I Made It

The initial stage of making the sword was done in a blacksmiths forge where I forged the metal parts into their general shape.

The sword consists of three metal parts:

I began by making the pommel. It started as a billet cut from a cylinder, which was forged out to bring it to a flatter cylinder with a slight taper towards the edges and then drilled a hole through it for the tang to go through.

The cross guard was forged from a flat bar. This was marked up and then a chisel was used to create the hole that the tang would go through. I then forged a taper on each side to bring it to its final shape. My first attempt was left in the fire for too long and ‘burnt’ causing it to be overly pitted, which meant I had to repeat the process to make a new one, which turned out better than the first as I had had more practice.

Then we come to the most substantial part, the blade, which began as a long flat bar slightly shorter then the final length of the sword. If I had more time at the forge I would have started with a shorter length so it would end up with a much stronger distal taper, which is an important factor for balance, without having to grind it down, which is much more time consuming. The blade was made by first forging the tang, then the fuller, which was done with a custom made tool, and then finally tapering out all the edges into a more blade like shape. This was the point at which the first major issue was introduced, which was that the edge was very wavy (in both directions), rather then straight. Once the forging was done there wasn’t really any way to fix this so the problem persists in the final incarnation.

After this I did a small amount of grinding to clean everything up and then fitted everything together. First the crossguard was placed on the tang. Then the tang was heated up and the grip, which was simply carver from an old hammer handle (the square space is because I was thinking about inlaying some horn, an idea I since abandoned), was pushed on to it, burning away the inside, which ensured a tight fit. Finally the pommel has placed on leaving a part of the tang protruding, which was then hammered down to hold everything in place.

Finally I added leather around the grip, which proved to be slightly difficult once the sword was fully assembled, so the edges ended up rather less than flush. The only particularly note worthy part of this stage is to thin the leather on the ends that will overlap with each other, which means there won’t be a large and obvious seam that would be likely to peel away after a while of handling.

This was then the state that the sword was left in for quite a while until I came back for summer from my first year at university, when I decided I wasn’t happy with how it was and I wanted to take it apart and improve it. This is where a lot of my troubles started.

The main problem I faced was the tool I was using to shape the blade: an angle grinder, which is very much not ideal for the task. A belt grinder would have been much more suitable, and even then a specialist belt grinder called a ‘linisher’ is what actual bladesmiths would usually use but these a bit too pricey for me so I had to make do. The main aims from the grinding were to: clean up all the surfaces to remove pitting, taper the blade and to enlarge the fuller.

Cleaning the surfaces was fairly straightforward and did not pose any real problems. Tapering the blade, however, proved much more difficult as it required the removal of a lot more material and it was quite easy to accidentally take off too much material as the blade thinned toward the edges. This is what ended up causing me to thin a section in the middle much more than I meant to, resulting in more of a ‘neck’ rather than the gradual taper I had intended. Expanding the fuller was probably the most troublesome part as the angle grinder was very much ill suited for the task. I ended up managing to grind almost all the way through at one point leaving a foil thin section with a crack through it (Rather embarrassingly this was very shortly after being warned to be careful about grinding through it). To solve this I had to get the hole welded up, which cleaned up fairly well and didn’t leave too much of a mark.

The next thing I wanted to do was to add some decorative file work to the hilt to make it look a bit nicer. This was probably one of the easiest stages and turned out pretty well. The straight lines were simply cut in with a small triangular file with the initial cut starting on a corner and then working across much like you would when cutting with a saw. The round cuts were started with the triangular file and then expanded with round files.

Then everything was polished. At this stage I did not really have the patience for polishing and was very aware that summer was running out and I wanted to move on to other things so the level of surface finish is not anything particularly amazing.

At this point I made the handle thinner and redid the leather by the same process as before but this time as it was detached from the rest of the sword I was able to get it much neater.

Finally It was time to reassemble the sword, and even this final step proved to be a bit tricky. The trouble was that in order to take it apart I had to grind away some of the tang as everything had been such a tight fit. This then meant that when the crossguard and grip were put back on they were incredibly loose and there was a lot of rattle to everything. To keep the cross guard tight I mixed up a paste with some wood glue the leather shavings I made from thinning the ends of the leather and then used this to fill in the gaps between the tang and the crossguard, which worked surprisingly well. The problem was that I thought that once the pommel was peened in place the grip would be held in place between the cross guard and the pommel. This was not the case. Once the pommel was peened in place, however, I couldn’t then remove it again as, without access to heat, I has to grind the the protruding part of the tang away to take everything apart and if I were to do this again I would not be left with enough to peen the pommel in place again. So I would have to leave it as it is: slightly wobbly.

That then concludes my first article. Im not really sure about a good way to ended it so I guess I will just stop.