This is the first of a series of backlog posts covering things i have been doing but never got around to writing about. Last December I did a silversmithing course to learn how to use the tools I inherited, as my previous attempts had been broadly unsuccessful, particularly in the realm of soldering. On this course I learnt a number of techniques including sawing (after breaking a great many blades), soldering, granulation and stone setting. After practicing on a number of pieces in copper I made two pieces in silver: A ring and a necklace.

Necklace

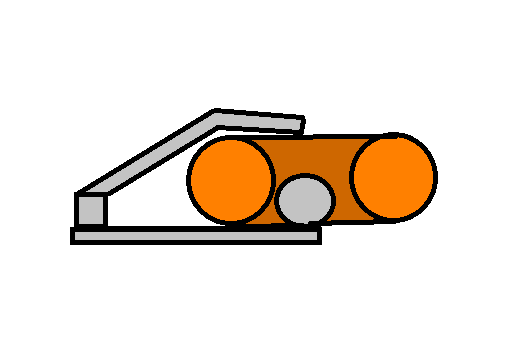

The necklace was based on an amber doughnut I had that was previously hung on some leather lace. The challenge for this was to make a setting that would allow the amber to spin freely. The solution is shown bellow in cross section. The key is in the granulation (silver melted into a ball) in the hole of the stone, which prevents it from falling out.

Ring

The ring is fairly plain with a black opal in a Cabochon setting with granulations on each side. The tricky part of this was soldering all the parts on without melting the previous solder off, since the balls on each side had to be done separately ( The ring had to be on its side so they didn’t slide off) and hard and medium solder (which melt at a higher temperature) had already been used to solder the ring shank and stone setting.